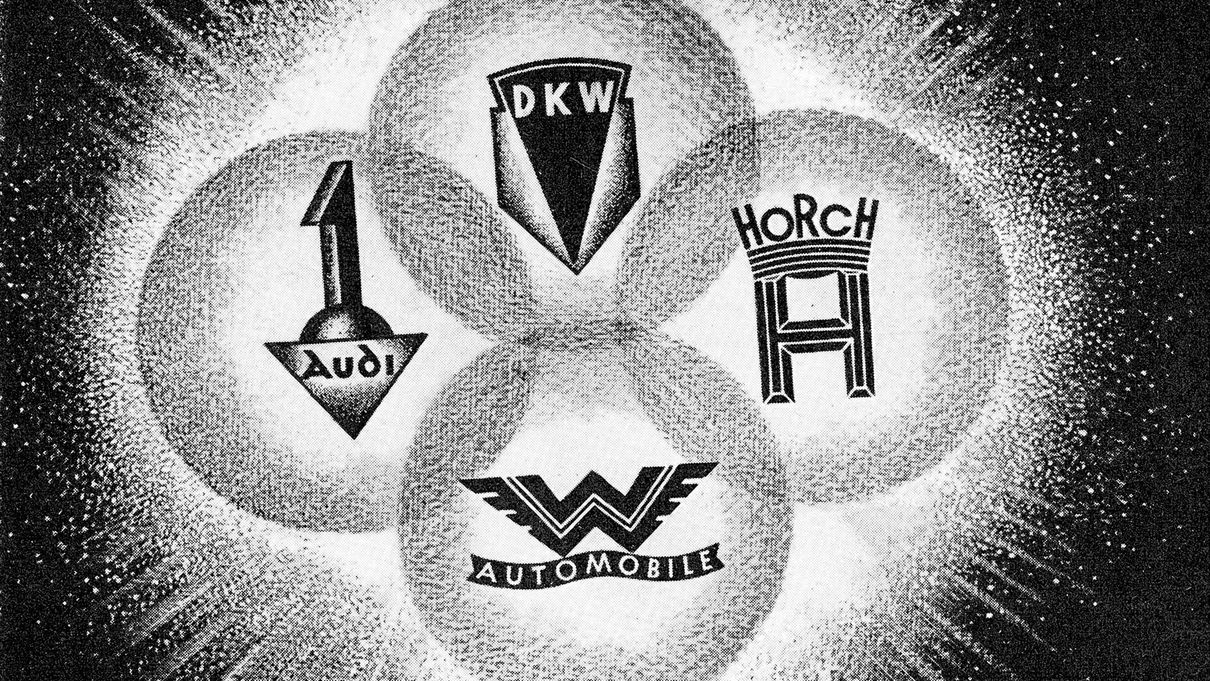

Four rings – four brands

Audi

The company established by August Horch in Zwickau on July 16, 1909 could not take its founder's name for competitive reasons. A new name was found for the company by translating Horch’s name, which in German means "hark!" or "listen!", into Latin. The second company established by August Horch therefore commenced trading as Audi Automobilwerke GmbH, Zwickau on April 25, 1910.

Audi

One of the keys to the success of the still-young Auto Union was the allocation of a specific market segment to each of the individual brands in order to create a coordinated model range. For the Audi brand, this prompted development of the Audi ‘Front’ Type UW, a midsize car that enabled the new group to make use of synergy benefits for the first time.

The principal feature of the new Audi was its front-wheel drive. DKW’s experience in the domain of front-wheel drive was simply adopted for a midsize vehicle. Its power unit was the Wanderer 2-litre, six-cylinder engine developed by Ferdinand Porsche; the body of the saloon version came from Horch’s body shop, and the convertibles were built by the highly reputable Dresden coachbuilder Gläser.

The Audi ‘Front’ Type UW – the designation meant a Type U with Wanderer engine – finally went into production in the spring of 1933. A year later, Audi’s production operations were transferred to the nearby Horch plant in order to free capacity at the Audi plant for the rising output of DKW front-wheel-drive models. Technically revised and equipped with an uprated 2.3-litre Wanderer engine, the new Audi Front 225 was unveiled at the 1935 Berlin Motor Show and remained on the market until 1938. The successor model, the Audi 920, also exhibited strong evidence of a modular construction system having been used. Both the chassis, now with conventional rear-wheel drive again, and the modern body styling were largely the same as the Wanderer W 23 six-cylinder model. This elegant car had an inline six-cylinder OHC engine developed by Horch, while the rear suspension adopted the DKW floating-axle principle. The first examples of the new car left the production line at Auto Union’s Horch factory in December 1938. The Audi 920 rapidly became a market success and a hit with customers.

This success was brought to an abrupt halt by the outbreak of the Second World War. Production of civilian vehicles was cut back to a minimum and the group’s operations switched to the production of armaments. For this, forced labourers, concentration camp prisoners and prisoners of war were also recruited. The last Audi of this era was built in April 1940. There would not be another Audi passenger car for a quarter of a century.

DKW

Originally founded in Chemnitz in 1902 as Rasmussen & Ernst, the company moved to Zschopau in the Erzgebirge region in 1907. It initially manufactured and sold exhaust-steam oil separators for steam power plants, vehicle mudguards and lights, vulcanisation equipment and centrifuges of all kinds. The company's founder Jörgen Skafte Rasmussen began to experiment with a steam-driven motor vehicle in 1916, registering DKW (short for Dampfkraftwagen – steam-driven vehicle) as a trademark in 1922. In 1919, the company began manufacturing two-stroke engines, initially in the form of a working toy-engine.. In 1921, this led to a change of name to “Zschopauer Motorenwerke J.S. Rasmussen OHG.” One year later, the first motorcycles left the factory in Zschopau under the brand name DKW.

DKW

On 29 June 1932, when the four companies – Audi, DKW, Horch and Wanderer – merged to form the Auto Union, Zschopauer Motorenwerke/DKW was chosen to be the parent company for legal reasons. Between 1932 and 1936, the administrative headquarters of Auto Union AG were located in the DKW head office building in Zschopau, before moving to Chemnitz in 1936.

If Rasmussen and his Zschopauer Motorenwerke were important for the establishment of Auto Union AG, DKW products were no less important for the economic development of the new company. DKW motorcycles and cars with their typical two-stroke engines served the lower end of the market (the price category between 345 and 3,400 Reichsmarks) and represented the high-volume Auto Union model range.

Biggest manufacturer of motorcycles in the world

DKW motorcycles were produced in such large quantities that in 1937 Auto Union with its DKW plant in Zschopau became the world’s largest motorcycle manufacturer, building a total of 55,470 motorcycles. The Zschopau-based manufacturer had already held this title before, in 1928.

A further important production area consisted of DKW stationary engines, of which there was an incredibly wide programme suitable for use in a variety of areas (e.g. agriculture, road construction, the fire brigade, the army and public authorities).

DKW products were acknowledged to be simple, practical, reliable, economical, durable and to perform well. In technological terms, the Zschopau-based company proved to be an innovative pioneer in the areas of two-stroke engines, front-wheel drives and body manufacturing (wooden and plastic bodies). This pioneering spirit also invigorated the innovative potential of Auto Union AG, which, from 1936 onwards, set up a Central Engineering Design Office (ZKB) in Chemnitz and a Central Testing Unit (ZVA) for all Auto Union brands.

Logistical tour de force

DKW car production as an inter-company alliance was a masterly logistical achievement: the engines were manufactured at the main factory in Zschopau and the bodies produced at the DKW body manufacturing plant in the Spandau district of Berlin; the four-cylinder models with rear-wheel drive were also built there. Assembly of the front-wheel-drive models took place at the Audi plant in Zwickau.

During the late 1930s, the DKW brand provided Auto Union with the necessary potential to counter the expected competition from the ‘KdF-Wagen’ (the People’s Car or Volkswagen) by launching an equivalent model, the DKW F 9. This made Auto Union the only car manufacturer in Germany to have an early response ready to challenge this Volkswagen model.

After the war, the hugely popular, proven DKW products enabled the newly founded Auto Union GmbH in West Germany to gain a foothold and also drove forward renewed automobile-industry activity in Saxony in East Germany.

Horch

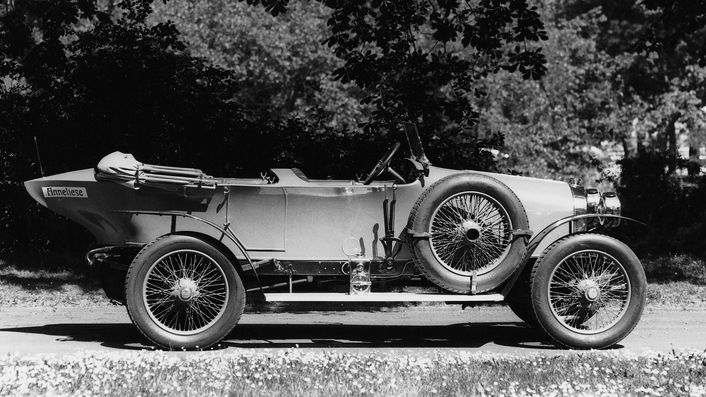

At the end of the 19th century, there were already a number of car manufacturers in Germany. One of them was August Horch & Cie., founded on November 14, 1899 in Cologne. August Horch was one of the pioneering figures in automobile engineering. Before setting up in business on his own, his professional experience had included three years in charge of automobile production at Carl Benz in Mannheim. In 1904, August Horch moved his business to Zwickau and transformed it into a joint-stock company.

Horch

The Horch Werke in Zwickau had never departed from the principle laid down by company founder August Horch, namely only to build good, powerful cars. Horch’s vehicles were among the leading products of the German automobile industry from the very start.

In the 1920s, extensive rationalisation measures were introduced in order to make assembly-line production more cost-effective. The launch of Germany’s first eight-cylinder car in the autumn of 1926 led to Horch products being numbered among the leading products of the German automobile industry. Whereas the Horch company had previously built only cars with four-cylinder engines, its engineers now concentrated entirely on large, distinguished eight-cylinder models.

Premium quality and cutting-edge technology

The Horch 8 became synonymous with elegance, luxury and leading-edge technology in German automobile construction. The Horch company also began to set the standard internationally. In 1932, Horch’s market share in the engine-size class above 4.2 litres in Germany was more than 44 percent.

When Auto Union AG was formed it was self-evident that the Horch brand should occupy the luxury market segment within the new group of companies. In addition, the Horch Body Design Office acted as the central design studio for all the group’s brands and laid down stylistic principles for the various models. The modern production technologies in use at the Horch factory became a benchmark for the group’s other factories.

From 1933 onwards, the Horch model programme was divided into large cars with straight-eight engines and smaller ones with V8 engines. When the sheer volume of luxury equipment available for a Horch made it clear that more powerful engines would be needed, the 5-litre straight-eight was given a camshaft with steeper lobes and its compression ratio increased in order to boost its power output to 120 hp. Similar measures applied to the smaller V8 engine, the power output of which went up from the original 62 hp to 82 hp for the 1937 model, culminating in a figure of 92 hp in 1939.

Extensive model development plans were mooted for Horch cars, ranging from new engines to streamlined bodies. Unfortunately the war years intervened and only a few exhibition cars and prototypes for testing were ever built.

From 1927 until peace-time production ended in 1940, about 42,000 Horch eight-cylinder cars were built. If vehicles supplied to the military authorities until the final cessation of production in 1942 are included, more than 70,000 eight-cylinder vehicles left the Zwickau factory during that period – a figure well above anything achieved by Horch’s German competitors.

Wanderer

In 1885 two mechanics, Johann Baptist Winklhofer and Richard Adolf Jaenicke, opened a bicycle repair workshop in Chemnitz. Shortly afterwards they began to make bicycles of their own, since demand at that time was very high. These were marketed under the brand name Wanderer, and in 1896 the company itself began to trade as Wanderer Fahrradwerke AG. Wanderer built its first motorcycle in 1902. The idea of branching out into car production was finally put into practice in 1913.

Wanderer

Wanderer Werke AG in Chemnitz had a diverse production programme at a very early stage: bicycles (from 1885), motorcycles (from 1902), office machines (from 1904), machine tools (from 1898) and cars (from 1913).

When Auto Union AG was formed in 1932, Zschopauer Motorenwerke AG as the parent company acquired the share capital of Audiwerke AG and Horchwerke AG directly. The fourth ‘ring’, however, the automobile division of Wanderer Werke, was acquired by purchase and a leasing agreement. Wanderer Werke, with its divisions for bicycles and small motorcycles, and office machinery and machine tools, remained a separate, independent company.

The mid-range segment of the Auto Union

Within Auto Union AG the Wanderer car brand was allocated the mid-size segment (prices between 3,875 and 8,250 Reichsmarks). Competition in this segment was very strong and came mainly from Opel and Daimler-Benz, and also BMW.

In terms of production volume and turnover, the Wanderer brand was second among the Auto Union companies, behind DKW. In 1937, 54,765 cars built by Auto Union AG were registered in Germany, a 25.3 percent share of the total (216,538). 19.5 percent of all registrations were for models built by DKW (42,143); Wanderer cars secured a 4.7 percent share (10,177); Audi and Horch were both below one percent.

Within the overall Auto Union programme, Wanderer models increasingly acquired the image of rather dull mid-size cars. In 1936, however, the Wanderer W 51 and the Wanderer W 25 K sports car with supercharged engine were introduced, featuring modern Auto Union body styling for the first time. This was taken up and implemented by the other Auto Union brands in the years that followed. The aim was to systematically reposition the Wanderer brand and give it a sporty, progressive image.

This development came to an abrupt end when the Second World War broke out in 1939. The last Wanderer cars left the factory in 1942, and after the war no attempts were made to revive the Wanderer brand in the automotive industry.

The Auto Union AG, Chemnitz

On 29 June 1932, Audiwerke, Horchwerke and Zschopauer Motorenwerke J. S. Rasmussen AG (DKW) merged on the initiative of the State Bank of Saxony to form Auto Union AG. A purchase and leasing agreement was concluded at the same time with Wanderer for the takeover of its motor vehicle division. The new company's head offices were in Chemnitz. Following the merger, Auto Union AG was the second-largest motor vehicle manufacturer in Germany. The company emblem consisted of four interlocking rings, intended to symbolise the inseparable unity of the four founder companies. The Audi, DKW, Horch and Wanderer brand names were retained. Each of the four brands was assigned a specific market segment within the group: DKW – motorcycles and small cars; Wanderer – midsize cars; Audi – cars in the deluxe midsize segment; and Horch – luxury cars at the top end of the market.

Audi worldwide

Models, products and services – switch to your country / sales region website and discover the regional diversity of Audi.